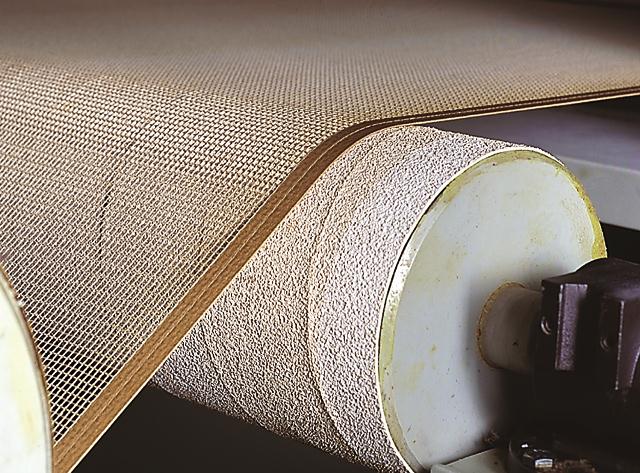

We are offering different varieties of PTFE (Teflon) Coated Fiber Glass Conveyor Belts. Which has the following features;

- Outstanding heat and cold resistance (from-70'C to + 260'C

- Excellent Chemical resistance

- Non-stick surface, easy to clean

- High dielectric strenght

- Dimensional stability

- Resistance to UV, IR and HF

- Non-tixic

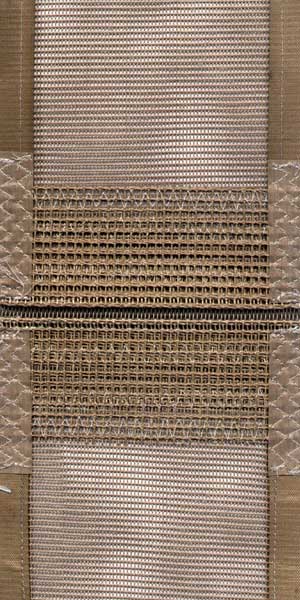

Conveyor belts are delivered ready for installation with seam and edge reinforcement. Several type of seams, joints, splice and edge reinforcements are available according to process type.

Seam Types :

1. PEEK Spiral

2. INOX Spiral

3. Bullnose

4. Metal lacing (Alligator)

5. Metal clipper

6. Castellated

7. Overlap'

8. Butt

9. Scarfed

10. Finger

Edge reinforcement types:

1. Reinforcement with PTFE / glass

2. Reinforcement with PTFE / Kevlar

3. Reinforcement with Pure PTFE Film

PTFE caoted glass fabrics are available in wide range of grades and qualities; A variety of thickness, length, weights and surface textures can be provided, in a diversity of styles for your specific use and requirements.

Fiberflon® has developed a full range of open-mesh belting products for Belt Dryers.

These belts can be used in Textile, Screen Printing, Packaging, Electronic, Food and other industries.

Some Properties:

- Outstanding temperature resistance (from -170ºC to +260ºC)

- Resistant to corrosive caustic cleaning agents

- Resistant to corrosive agents

- Low thermal mass

- Controlled porosity

- Superior non-stick surface, easy to clean

- High dielectric strength

- Dimensional stability

- Resistance to UV, IR and HF

- Non-toxic

- Superior tracking

Fiberflon open mesh belts are used in screen printing to transport imprinted materials through drying ovens and cooling chambers. These belts are long lasting and perform well over a wide range of operating temperatures.

Fiberflon belt fabrication department can supply a wide variety of splices and edge reinforcements in order to respond customer’s specific applications. Different constructions of open mesh fabrics are available with Kevlar , Nomex and Fiberglas.

|

PTFE / GLASS - OPEN MESH FABRIC SERIES |

|||||

|

Style |

Standard width |

Thickness |

Weight |

PTFE content |

Tensile |

|

1850,2050,2300,2500 2750,3200,3350,3650 |

0,90 |

460 |

31 |

3000 |

|

|

1530,1780,3150 |

0,70 |

580 |

23 |

2500 |

|

|

2050,2650,3200,3650 |

0,80 |

430 |

23 |

1500 |

|

|

2500,3350 |

1,20 |

550 |

33 |

2300 |

|

|

2050,2500,2750,3350 |

1,20 |

580 |

31 |

3000 |

|

|

3650 |

0,90 |

600 |

45 |

2000 |

|

|

2050,3350,3600 |

1,20 |

930 |

36 |

3600 |

|

|

PTFE / GLASS - BLACK ANTI-STATIC OPEN MESH FABRIC SERIES |

|||||

|

Style |

Standard width |

Thickness |

Weight |

PTFE content |

Tensile |

|

1850,2050,2300,2500 2750,3200,3350,3650 |

0,90 |

460 |

31 |

3000 |

|

|

1530,1780,3150 |

0,75 |

530 |

22 |

2500 |

|

|

2050,2650,3200,3650 |

0,80 |

430 |

23 |

1500 |

|

|

2500,3350 |

1,20 |

550 |

33 |

2300 |

|

|

2050,2500,3350 |

1,20 |

580 |

31 |

3000 |

|

|

PTFE / ARAMID (KEVLAR®) - OPEN MESH FABRIC SERIES |

|||||

|

Style |

Standard width |

Thickness |

Weight |

PTFE content |

Tensile |

|

2050,2600,3350 |

0,90 |

350 |

49 |

3500 |

|

|

3350 |

1,00 |

450 |

49 |

5000 |

|

|

ARAMID-GLASS - OPEN MESH FABRIC SERIES |

|||||

|

Style |

Standard width |

Thickness |

Weight |

PTFE content |

Tensile |

|

2050, 3350 |

1,20 |

680 |

no PTFE coat |

5700 |

|

|

2150,2800,3350 |

1,50 |

650 |

33 |

4500 |

|