Go To : Machines > Dongnam Industrial Co,. Ltd > Heat-Setting_Machine

Features :

- DNH TYPE HEAT SETTING MACHINE IS DESIGNED TO PROCESS THE CIRCULAR KNITTED FABRIC BEING COMPOSED OF

- SYNTHETIC AND BLENDED YARNS.

- THE MACHINE COMPRISES OF THE OVER FEEDING SECTION, HEATING, COOLING SECTION, PRESS ROLLER AND FOLDING SECTION.

- IT IS POSSIBLE TO REDUCE THE HEAT DIFFERENCE BETWEEN THE INSIDE AND OUTSIDE OF THE HEATING CHAMBER AS

- THERE IS DIRECT HEATING SYSTEM BY MEANS OF GAS OR THERMO-OIL.

- THE MACHINE MAKE MORE EASY TO CONTROL THE THICK KNITTED FABRIC TO GET THE REQUIRED WIDTH BY USING THE STRONG HOT WIND.

- THE MACHINE EQUIPPED WITH A DIGITAL CONTROL SYSTEM TO CONTROL ACCURATELY THE MAIN SPEED AND OVER FEED.

- AS A RESULT, IT IS POSSIBLE TO SOLVE THE PROBLEMS LIKE THE LOOP TWIST.

- THE MACHINE CAN BE CONTROLLED EASILY BY CENTRALIZED CONTROL SYSTEM.

Specification :

| Model | DNH-1400 |

| Width | 1400mm (ROLLER), 1300mm (WORKING) |

| Production Capacity | 3 ~ 5 TON/22H/DAY |

| Machine Speed | 10 ~ 20 m/min. |

| Total Electric Consumption | 7.3KW. |

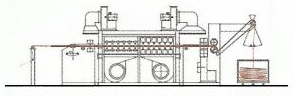

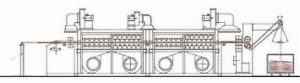

Layout Drawings :

2 Line 1 Chamber |

2 Line 2 Chamber |

Selection of Major Components :

| Type of Heating Source |

Gas Burner and Thermo Oil |

| Number of Heating Chamber |

1 Chamber or 2 Chambers |

| Type of Plaiter |

Normal or Precision |

| Number of Processing Line |

1 Line or 2 Lines |