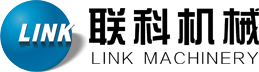

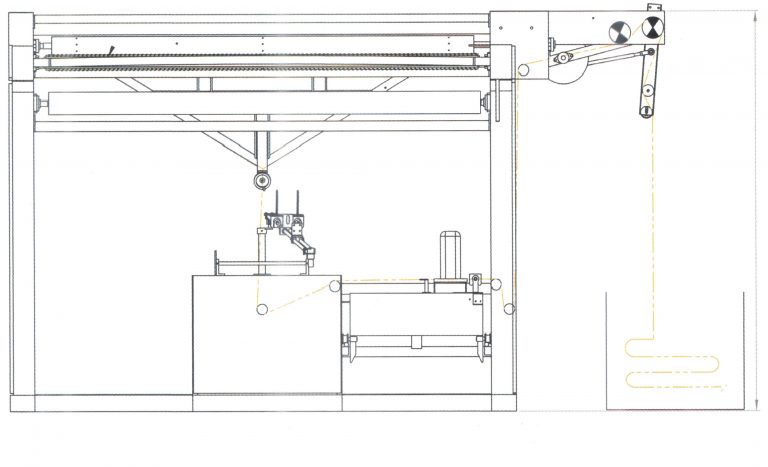

Automatic Seaming Machine

The double thread seaming apply to the seaming process for knit fabric that need to seam and dye and dry by columnar drier. It uses double thread high speed s machine. There is not raw edge after dyed and equal to the three worker' s workload. Based on the practical experience in this industry, against of knit fabric in rayon, and cotton fabric that needs to be remove lin t, LINK choose special yarn I n suitah'e strength and different needle to saw. There is not problem of raw edge that lead to bad drying during drying by columnar drier and not problem of big stitch during subsequent rope opening. Effectively save searnlng cost and improve production efficiency.

Technical Advantages:

- Press edge device replaces traditional blowing way by air compressor, use press edge device to make edge more flat and get better seaming effect, save air compression cost.

- The break thread detector use reasonable crossing structure, and high quality sensors. Automatic stop against break thread and make the operation more easy.

- Against of different knit fabric and different production process, based on the practical experience in this industry, recommend suitable thread to directly seam, avoiding quality problem from thread trials.

Technical Parameters:

| Machine Type | LK-FB-2650 |

| Working Width | 2650mm |

| Running Speed | 0~60m/min(Single Line) |

| Running Speed | 0~50m/min(Double Line) |

| External Dimention | L4100*W2910*H2350 |