Features :

- Tube Compactor is designed to control the effective shrinkage and high dimensional stability of knitted fabrics as single jersey and double jersey fabrics.

- It is machanically possible to adjust the shrinkage ratio upto 18% depends on the type of fabrics.

Constructional Feature :

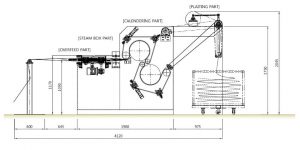

Entering Section

The Device for the regular supply at fabric by utilizing the function of sensor.

Guide Section

It comprises of guide width adjustment device and over feeding & sensor device.

1st & 2nd Heating Section

The main function of this section is for shrinkage control.

It comprises of steam box, felt tension & balance device, felt compressive ratio adjustment device (2 set of felt blanket), steam heating roller and telfon sheet supply device.

Driving by Inverter control

Controlled by Centrlized Control System

Specification :

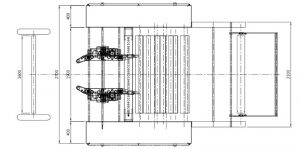

| Working width |

1300mm. |

| Roller width |

1400mm. |

| Working speed | 3-45 m/min. |

| Driving control |

Inverter syetem |

| Power consumption |

11.6 kw |

| Steam consumption |

200 kg /cm² |

| Steam pressure |

3-5 kg /cm² |

| Packing dimension |

27 CBM |

| Gross weight |

4500 kg |